| STRESSES ON CUTTING EDGES WHEN MILLING |

| When milling each individual tooth is only in contact with the workpiece for a maximum of 180° per revolution. Consequently certain conditions affect the cutting edges: | |

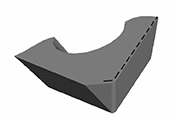

| A) SUDDEN VARIATIONS The sudden variation in cutting forces on the insert could lead to small gashes on the cutting edges. |

|

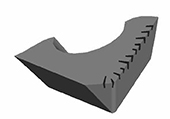

| B) THERMAL EFFECT Temperatures of up to 1,000° can develop when the cutting edge enters the workpiece. The thermal effects alter as the cut progresses, this combined with the effect of the insert being exposed to the air or coolant (in the non-cutting position) could lead to cracks appearing along the cutting edge. |

|

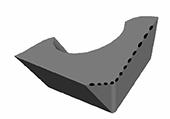

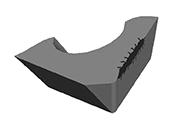

| C) BREAKOUTS Breakout or chipping develops through overworking the insert. REMEDY *check cutting edge condition *check facets and/or radius *use a tougher grade |

|

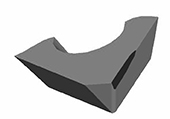

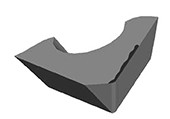

| D) WEAR DOWN THE CLEARANCE FACE Normal condition when milling for a period of time. REMEDY *increase feed *use a more wear resistant grade *lower cutting speed |

|

| E) PLASTIC DEFORMATION High cutting temperatures can lead to this condition. REMEDY *reduce cutting speed *use a grade which is more resistant to this condition |

|

| F) SPLINTERING Change in temperatures and intermittent cutting can lead to splintering of the cutting edge. REMEDY *alter cutting data, reduce load *use a tougher grade carbide *adjust entry and exit conditions |

|

| G) CRATERING Cratering in general is not a reason for short tool life. REMEDY *reduce cutting speed *use a more wear resistant grade |

|

| H) BUILT UP EDGES This condition occurs when a cutting speed is too low. REMEDY *alter cutting data (increase) *alter geometry, positive cutting angle |

|