| RECOMMENDED CALCULATIONS When Using Ball Nose Copy Milling Cutters |

| I.S.O CODE |

MATERIAL | GRADE | SURFACE SPEED m/min |

FEED / TOOTH OPERATION (fz mm) |

||

| I | II | III | ||||

| P | Plain carbon steel - Free cutting steel | T40/T60 | 200 | 0.12 | 0.2 | 0.25 |

| Structural alloy steel. - Cast steel | T40/T60 | 160 | 0.12 | 0.18 | 0.25 | |

| Heat treatable steel, medium strength. - Case hardening steel. | T40/T60 | 160 | 0.12 | 0.18 | 0.25 | |

| Stainless steel, ferritic martensitic | T40/T60 | 130 | 0.12 | 0.18 | 0.27 | |

| Heat treatable steel, high strength. - Nitriding steel - Tool steel. | T40/T60 | 130 | 0.1 | 0.16 | 0.2 | |

| M | Stainless steel austenitic | T40 | 240 (80) |

0.1 | 0.12 | 0.15 |

| K | Aluminium alloys, long chipping | K10 | 900 | 0.2 | 0.3 | 0.4 |

| Copper alloys, long chipping. - Pure metals, soft. - Thermoplastics | K10 | 250 | 0.15 | 0.25 | 0.3 | |

| Grey cast iron | T60 | >200 | 0.15 | 0.25 | 0.35 | |

| Alloyed grey cast iron | T60 | >200 | 0.12 | 0.2 | 0.25 | |

| Nodular cast iron | T60 | <200 | 0.15 | 0.2 | 0.3 | |

| Malleable cast iron | T60 | 160 | 0.12 | 0.2 | 0.25 | |

| Magnesium alloys | K10 | 200 | 0.12 | 0.2 | 0.25 | |

| Titanium alloys, medium strength | K10 | 80 | 0.15 | 0.2 | 0.25 | |

| Nickel based alloys, medium strength | T60 | 60 | 0.2 | 0.25 | 0.3 | |

| Aluminium alloys, short chipping | K10 | 250 | 0.15 | 0.2 | 0.3 | |

| Copper alloys, short chipping | T60 | 250 | 0.12 | 0.2 | 0.25 | |

| Heat resistant nickel based alloys, high strength | T60 | 40 | 0.2 | 0.25 | 0.3 | |

| Titanium alloys, high strength | K10 | 60 | 0.12 | 0.2 | 0.3 | |

| Chilled cast iron | T60 | 60 | 0.12 | 0.15 | 0.2 | |

| Duroplastics | K10 | 300 | 0.15 | 0.2 | 0.3 | |

|

|

|||||

| OPERATION | ROUGHING | FINISHING | ||||

| I | II | III | ||||

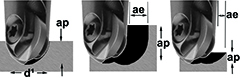

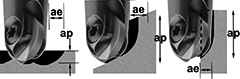

| ap= | 0.5.d¹ 1.d |

>0.5.d¹ 0.2.d - 0.5.d¹ |

0.2.d - 0.5.d¹ 0.2.d - 0.5.d¹ |

< 0.2.d¹ < 0.2.d¹ |

0.2.d¹ - 0.5 < 0.2.d¹ |

> 0.5.d¹ < 0.2.d¹ |

| ae= | ||||||

| Speeds to use for varing depths of cut | 1 x rpm |

1.1 x rpm | 2 x rpm | 1.3 x rpm | 1 x rpm | |

| If several values are valid please choose the smallest one. | ||||||

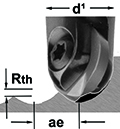

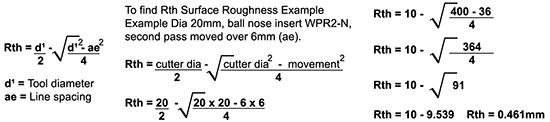

| Theoretical surface roughness | |

|

|